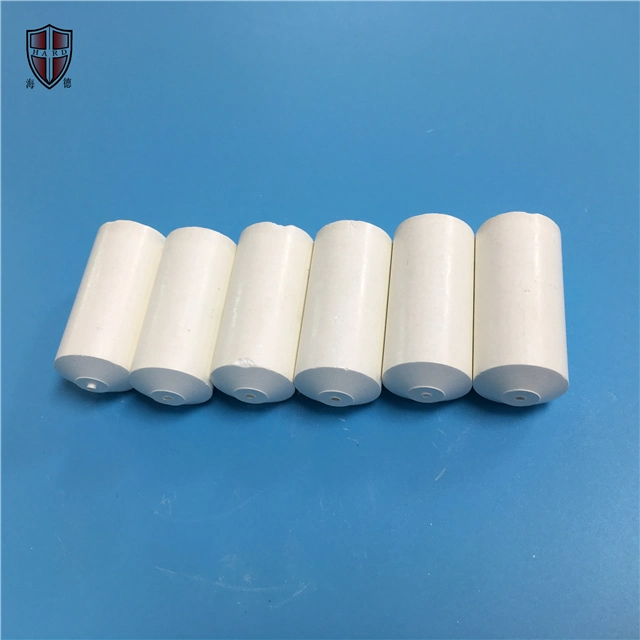

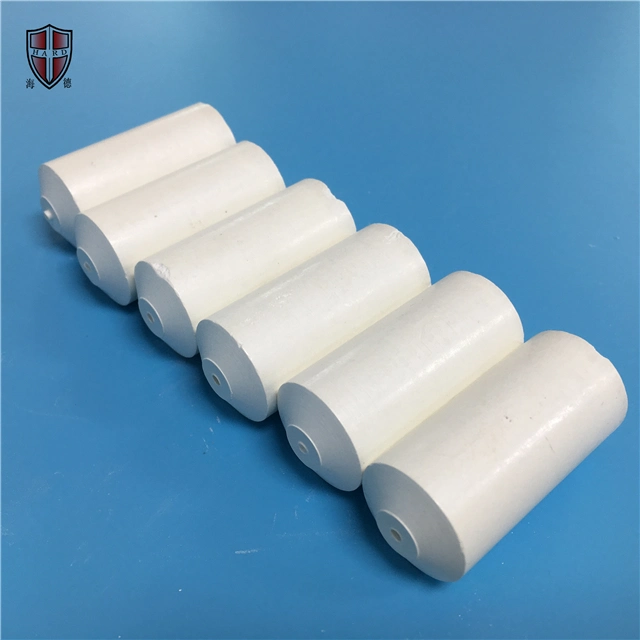

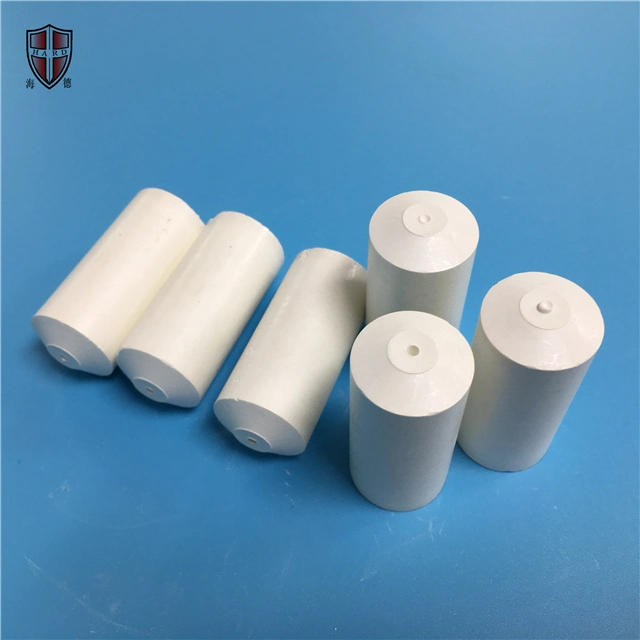

High Temperature Bn Boron Nitride Ceramic Machinable Rod Shaft Block

Description

Basic Info.

| Model NO. | BN-002 |

| Lead Time | 10 Days |

| Compressive Strength | 800 MPa |

| Chemical Formula | Bn |

| Weight | Customized |

| Content | 43.6% Boron, 56.4% Nitrogen |

| Alias | White Graphite |

| Color | White |

| Transport Package | Box/Carton / Plastic Bag / Wooden Case… |

| Specification | Customized |

| Trademark | Hard |

| Origin | Shenzhen, China |

| HS Code | 6914100000 |

| Production Capacity | 10, 000, 000PCS/Month |

Product Description

high temperature BN boron nitride ceramic machinable rod shaft block Reputation depends on quality, quality comes from Hard.Boron Nitride Ceramics:

Boron nitride is a crystal composed of a nitrogen atom and a boron atom. The chemical composition is 43.6% boron and 56.4% nitrogen with four different variants: hexagonal boron nitride (HBN), rhombohedral boron nitride (RBN), cubic boron nitride (CBN) and wurtzite nitrogen. Boron (WBN).

Boron Nitride Ceramics properties:

Boron nitride ceramics have good heat resistance, thermal stability, thermal conductivity, high temperature dielectric strength, and are ideal heat dissipation materials and high temperature insulation materials. Boron nitride has good chemical stability and is resistant to most of the molten metal. It also has good self-lubricating properties. Boron nitride products have low hardness and can be machined with an accuracy of 1/100 mm.

Data Sheet↓

| Item | Unit | Typical Values |

| Physical Properties | ||

| Color | White | |

| Chemical Formula | / | BN |

| Content | 43.6% boron, 56.4% nitrogen | |

| Water Absorption | 0 | |

| Mechanical Properties | ||

| Rockwell Hardness(45N) | R45N | 40 |

| Vickers Hardness (Load 500g) | Gpa(Kg/mm²) | 24.5-28.2 |

| Flexural Strength | Mpa | 350-600 |

| Compressive Strength | Mpa | 800 |

| Modulus of Elasticity | Gpa | 441/475 |

| Thermal Properties | ||

| Thermal Conductivity | W/m·K | 25.25-41 |

| Thermal Expansion Coefficient | 10-6/ºC | 3.8-5.12 |

| Melting point | °C | 3000 |

| Maximum Use Temperature | °C | 1800 |

| Electronic Properties | ||

| Dielectric Constant | 3000K | 9.10 |

| Volume Resistivity(400~600ºC) | Ω.cm | 2.3~5.6M |

Application :Boron nitride can be used in the manufacture of high-temperature containers for metallurgical melting, semiconductor heat-dissipating insulation parts, high-temperature bearings, thermowells, and glass forming dies.The boron nitride usually produced is a graphite type structure, commonly known as white graphite. The other is a diamond type, which is similar to the principle that graphite is converted into diamond. Graphite-type boron nitride can be converted into diamond-type boron nitride at high temperature (1800 ° C) and high pressure (800 MPa). The boron nitride has a B-N bond length (156 pm) similar to that of diamond at C-C bond length (154 pm), and its density is similar to that of diamond. Its hardness is comparable to that of diamond, and heat resistance is better than diamond. It is a new high temperature resistant superhard material for making drills, abrasive tools and cutting tools.

Company Information

Shenzhen Hard Precision Ceramic CO.,Ltd founded in 2007, located in Shenzhen of China. We are a company that integrates development, design, molding, sintering, production and sales of precision ceramic products. After 10 years of development, we have cooperated with more than 2000 customers and 60 universities; Our factory covers an area of 2000 square meters, 50 employees, and annual production value of nearly 20 million. We have a higher visibility and better reputation in the same industry.Our products include ceramic rods, tubes, plates, blocks and precision parts for industrial. We have all-line high precision equipments from ceramic forming, sintering to precision machining. Hope for a wide range of sincere cooperation with customers at home and abroad.

Why Choose Us?

1.12 years of professional production industrial ceramics factory2.High quality products with low price3.High precision parts with lowest tolerance4.Short time for production 5.Has a group of experienced, professional and efficient R&D team6.Has a good reputation in China and abroad.7.MOQ is not limited, small quantity is welcome.8.Vigorous team and good after-sales service

Product ShowFactory ShowPackaging & ShippingOur TeamFAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Contact Us

Our Contact