Vhandy Cubic Bn Boron Nitride Ceramic Sleeve

Product Description Boron nitride material Boron nitride materials have high thermal stability, chemical stability and e

Description

Basic Info.

| Model NO. | Boron Nitride |

| Origin | China |

| HS Code | 8543709990 |

| Production Capacity | 50000 |

Product Description

Product Description

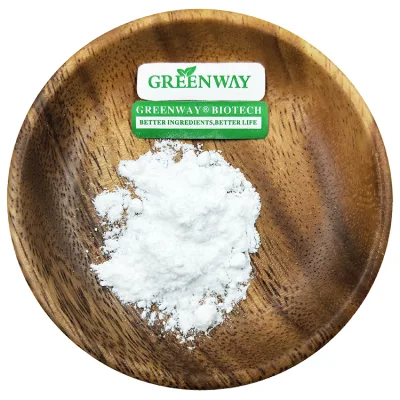

Boron nitride material

Boron nitride materials have high thermal stability, chemical stability and electrical insulation, as well as high thermalconductivity, dielectric properties and easy-to-process products. Its melting point is as high as 2800ºC, which is botha typical electrical insulator and an excellent heat conductor.

| Boron nitride ceramic technology parameters | ||

| Grade | PENSC-A | |

| Chemical structure | % | 99 |

| Other components | no | |

| Density | g/cm3 | >2 |

| Hardness | HL | 300 |

| Flexural Strength | Mpa | 35 |

| Coefficient of thermal expansion | (10-6/K) | -1~2.5 |

| Thermal conductivity at 20ºC | W/mk | 50 |

| MAX-Temperature of use | oxidizing | 900ºC |

| vacuum | 1800ºC | |

| inert | 2200ºC | |

| RT Resistivity | Ω.cm | >1014 |

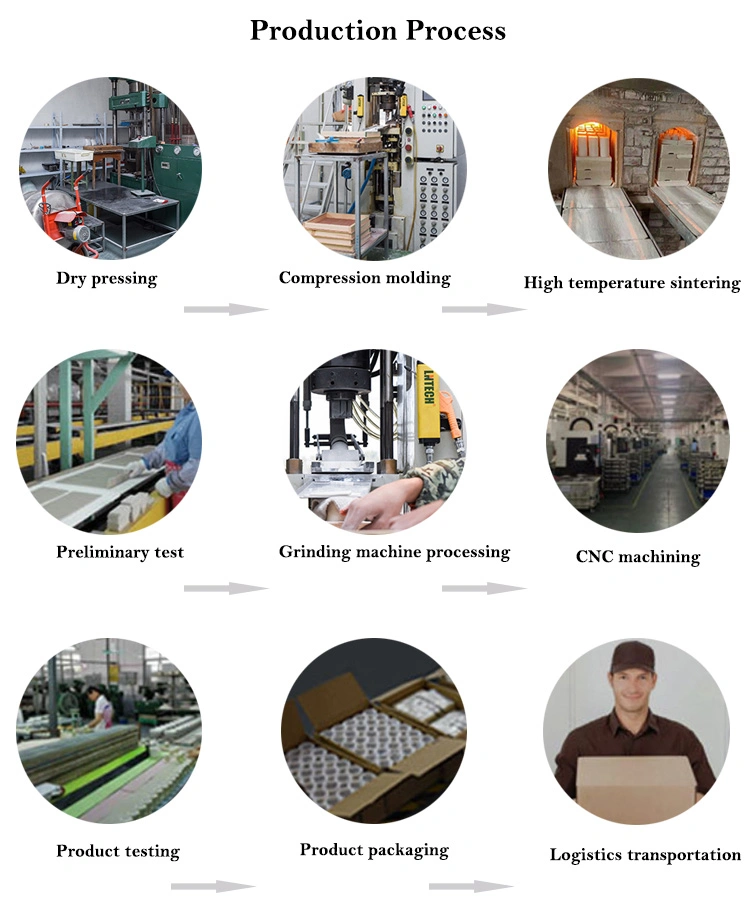

Product featuresFeatures & AdvantagesAdopting international leading manufacturing boron nitride powder, Ensure the purity of materials and Hightemperature resistance. Adopting cold-isostatic pressing and bidirectional hot-pressing sintered technology,High density and longer lifetime.Stable and mature production technology and process, not use any binder,ensure material stability.

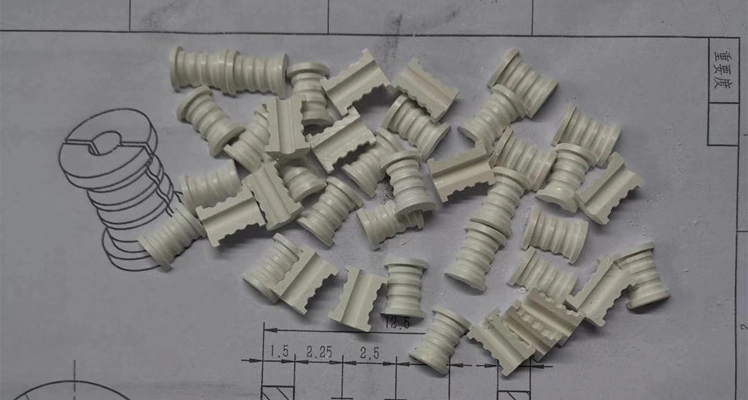

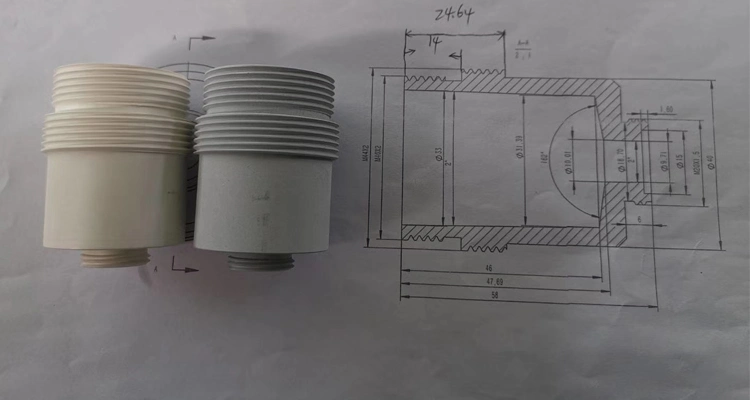

Shooting in kind

Certifications

FAQQ: Are you trading company or manufacturer?

A: We are manufacturer

Q: How long is your delivery time?

A: Generally within 30 working days, it is according to quantity

Q: Do you provide samples? Is it free or extra?

A: The samples can be provided, but the shipping cost should be on buyer's account

Q: What is your term of payment?

A: Payment<=10000 USD, 100% in advance. Payment>=10000 USD, 70% T/T in advance, balance before shipment.

Prev: Supply CAS 10043

Our Contact

Send now