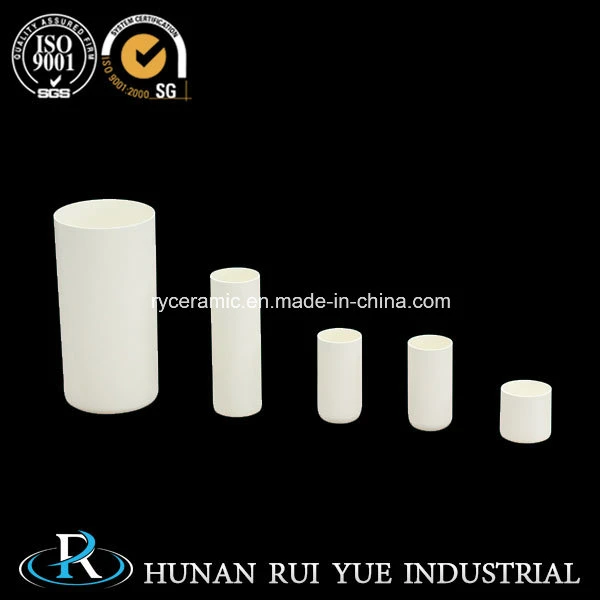

Bn Ceramic/Boron Nitride Coatings for The Metal Processing Market

Description

Basic Info.

| Model NO. | RY-C397 |

| Classification | Hybrid Insulation Materials |

| Certification | ISO9001 |

| Color | White |

| Name | 99.99% Pyrolytic Boron Nitride |

| Used | Hpbn Ceramic |

| Item | Structure Ceramic, Pbn Crucible, |

| Product | Hot Pressed Boron Nitride |

| Transport Package | Carton |

| Specification | 100-500cc |

| Origin | China |

| HS Code | 8547100000 |

| Production Capacity | 5000PCS Per Month |

Product Description

BN Ceramic/Boron Nitride Coatings For The Metal Processing Market

Specifications

BN99 ; BN+Ca ; BN+Si ; BN+Al2O3 ; BN+SiC ; BN+ZrO2 ; BN+AlN

Advantage

Non-toxic

High purity

Low density

Chemically inert

Non-porous

One of the highest dielectric strengths known

Good thermal conductivity

Tensile strength increases with temperature

Excellent thermal shock resistance

High oxidation resistance

Negligible outgassing

Advantageous anisotropy (electrical, mechanical, and thermal)

It is produced in a hot pressed form and the resulting material properties are anisotropic relative to the press direction. In fact, the material properties can vary considerably depending on the direction or the grade of the material. Futhermore, it is easily machined into complex shapes using standard carbide tooling. The operation temperatures range from 900°C for oxidizing environments to 2200°C for inert environments.TECHNICAL PROPERTIES

Type | 99BN | CBN | ABN | ZBN |

Main Content | BN>99% | BN>98.5% | BN+AlN | BN+ZrO2 |

Binder | B2O3 | CaB2O6 | ALBO3 | B2O3 |

Density (g/cm3) | 1.95-2.0 | 2.0-2.1 | 2.6 | 2.95 |

Flexural Strength (Mpa) | 30 | 100 | 200 | 200 |

Compressive Strength (Mpa) | 100 | 280 | 350 | 380 |

Electrical Resistivity (ohm.cm) | >10^14 | >10^13 | >10^14 | >10^12 |

Max. Working Temp. (°C) air | 900 | 900 | 900 | 1000 |

Max. Working Temp. (°C) inert gas | 2400 | 2400 | 2100 | 1800 |

Max. Working Temp. (°C) vacuum | 2200 | 2200 | 1900 | 1800 |

Thermal Conductivity (W/m.K) | 20 | 35 | 50 | 30 |

Expansion Coefficient 25 - 1000 °C (10^-6/K) | 1.5 | 2 | 4.5 | 2 |

3:Workshop Photo:

4:Our Service:5:What can we do for you?

1. Sample is available.

2. Independent R&D, ISO manufacture, precise quality standards, modern logistics management, and sound marketing strategy.

3. Inquiry replied within 24 hours.

4. Patented products.

5. OEM or ODM is available.

6. Some extra accessories can be supplied.

7.The larger quantity you order,the more competitive prices you'll get.

8. Necessary Certificates can be supplied.

9:Why To Choose Us

1. Low MOQ:

It won't occupy too much of your money to help you to test the market you're going to enter.

2. R & D Center and Factory:

We have our own R & D center and factory, so we can supply you products at competitive price.

3. Good Service :

We treat clients as friends.

4. Good Quality :

We import top quality accessories to manufacture our products, we have confident we can offer you the best quality.

5. After-sales service:

One year's guarantee. Wearing accessories comes with the products to help you to reduce the repair bill.

Prev: Cubic Boron Nitride CBN

Next: High

Our Contact